AS1324 データシートの表示(PDF) - austriamicrosystems AG

部品番号

コンポーネント説明

一致するリスト

AS1324 Datasheet PDF : 21 Pages

| |||

AS1324

Datasheet - Application Information

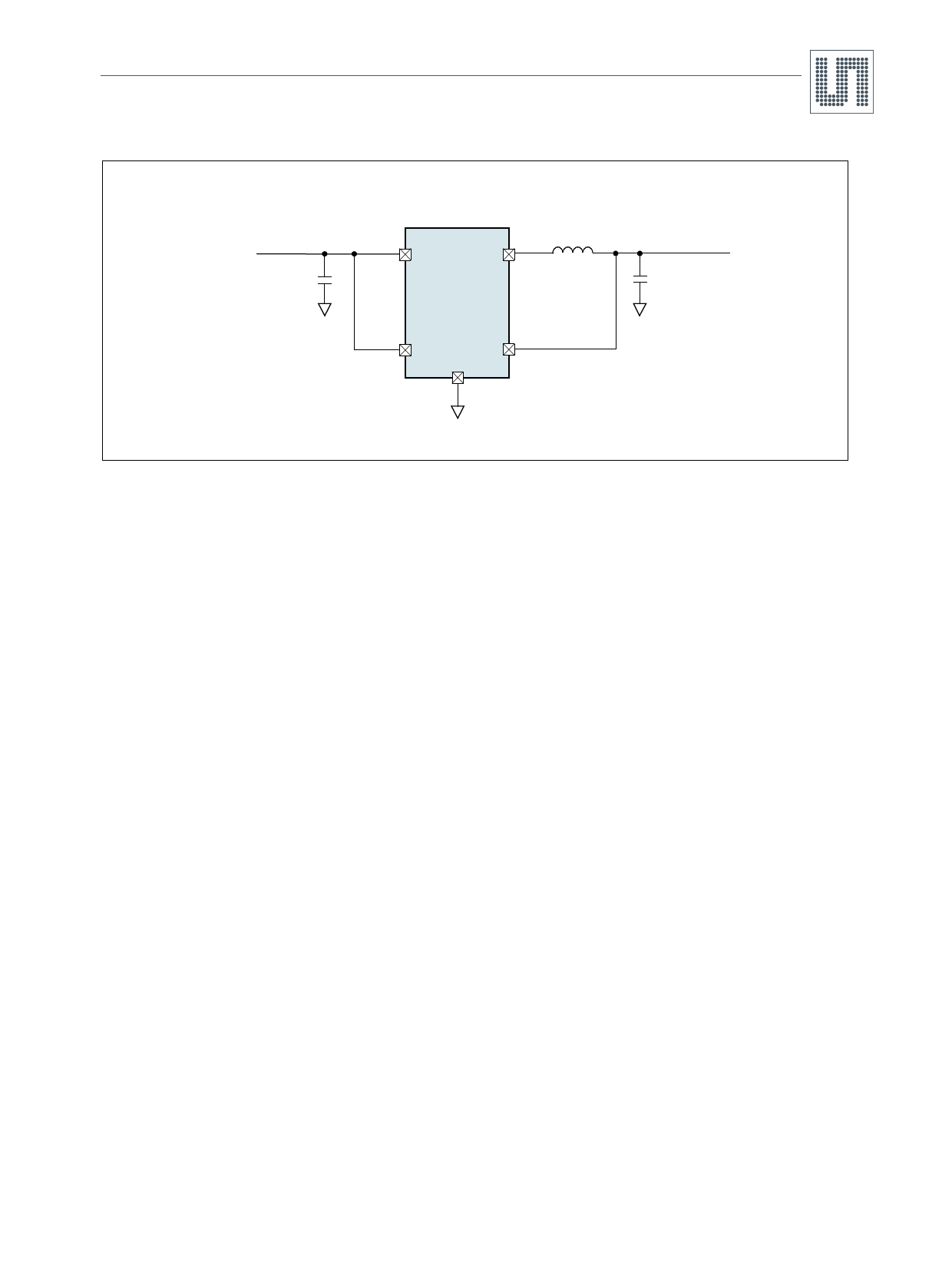

Figure 25. Single Li-Ion 1.8V/600mA Regulator for Low Output Ripple

VIN

2.7 to 4.2V

CIN

10µF

4.7µH

4

3

VIN

SW

AS1324-18

1

5

EN

VOUT

2 GND

COUT

22µF

VOUT

1.8V

600mA

9.1 External Component Selection

9.2 Inductor Selection

For most applications the value of the external inductor should be in the range of 2.2 to 6.8µH as the inductor value has a direct effect on the

ripple current. The selected inductor must be rated for its DC resistance and saturation current. The inductor ripple current (∆IL) decreases with

higher inductance and increases with higher VIN or VOUT.

In Equation (EQ 2) the maximum inductor current in PWM mode under static load conditions is calculated. The saturation current of the inductor

should be rated higher than the maximum inductor current as calculated with Equation (EQ 3). This is recommended because the inductor

current will rise above the calculated value during heavy load transients.

∆IL = VOUT × -1----–--L---V----×--V---O-----fI---U-N------T---

(EQ 2)

ILMAX

=

IOUTMAX

+

∆----I--L-

2

Where:

f = Switching Frequency (1.5 MHz typical)

L = Inductor Value

ILmax = Maximum Inductor current

∆IL = Peak to Peak inductor ripple current

The recommended starting point for setting ripple current is ∆IL = 240mA (40% of 600mA).

(EQ 3)

The DC current rating of the inductor should be at least equal to the maximum load current plus half the ripple current to prevent core saturation.

Thus, a 720mA rated inductor should be sufficient for most applications (600mA + 120mA). A easy and fast approach is to select the inductor

current rating fitting to the maximum switch current limit of the converter.

Note: For highest efficiency, a low DC-resistance inductor is recommended.

Accepting larger values of ripple current allows the use of low inductance values, but results in higher output voltage ripple, greater core losses,

and lower output current capability.

The total losses of the coil have a strong impact on the efficiency of the dc/dc conversion and consist of both the losses in the dc resistance and

the following frequency-dependent components:

1. The losses in the core material (magnetic hysteresis loss, especially at high switching frequencies)

2. Additional losses in the conductor from the skin effect (current displacement at high frequencies)

3. Magnetic field losses of the neighboring windings (proximity effect)

4. Radiation losses

www.ams.com/DC-DC_Step-Up/AS1324

Revision 1.06

11 - 21