MAX5391 データシートの表示(PDF) - Maxim Integrated

部品番号

コンポーネント説明

一致するリスト

MAX5391 Datasheet PDF : 14 Pages

| |||

MAX5391/MAX5393

Dual 256-Tap, Volatile, Low-Voltage

Linear Taper Digital Potentiometers

Detailed Description

The MAX5391/MAX5393 dual 256-tap, volatile, low-

voltage linear taper digital potentiometers offer three end-

toend resistance values of 10kΩ, 50kΩ, and 100kΩ. Each

potentiometer consists of 255 fixed resistors in series

between terminals H_ and L_. The potentiometer wiper,

W_, is programmable to access any one of the 256 tap

points on the resistor string.

The potentiometers in each device are programmable

independently of each other. The MAX5391/MAX5393

feature an SPI interface.

Charge Pump

The MAX5391/MAX5393 contain an internal charge pump

that guarantees the maximum wiper resistance, RWL, to

be less then 200Ω for supply voltages down to 1.7V. Pins

H_, W_, and L_ are still required to be less than VDD +

0.3V. A bypass input, BYP, is provided to allow additional

filtering of the charge-pump output, further reducing clock

feed through that may occur on H_, W_, or L_. The nomi-

nal clock rate of the charge pump is 600kHz. BYP should

remain resistively unloaded as any additional load would

produce a ripple of approximately IBYP/(600kHz x CBYP)

volts. See the Charge-Pump Feedthrough at W_ vs.

CBYP graph in the Typical Operating Characteristics for

CBYP sizing guidelines with respect to clock feedthrough

to the wiper. The value of CBYP does affect the startup

time of the charge pump; however, CBYP does not impact

the ability to communicate with the device, nor is there a

minimum CBYP requirement. The maximum wiper imped-

ance specification is not guaranteed until the charge

pump is fully settled. See the BYP Ramp vs. CBYP graph

in the Typical Operating Characteristics for CBYP impact

on charge-pump settling time.

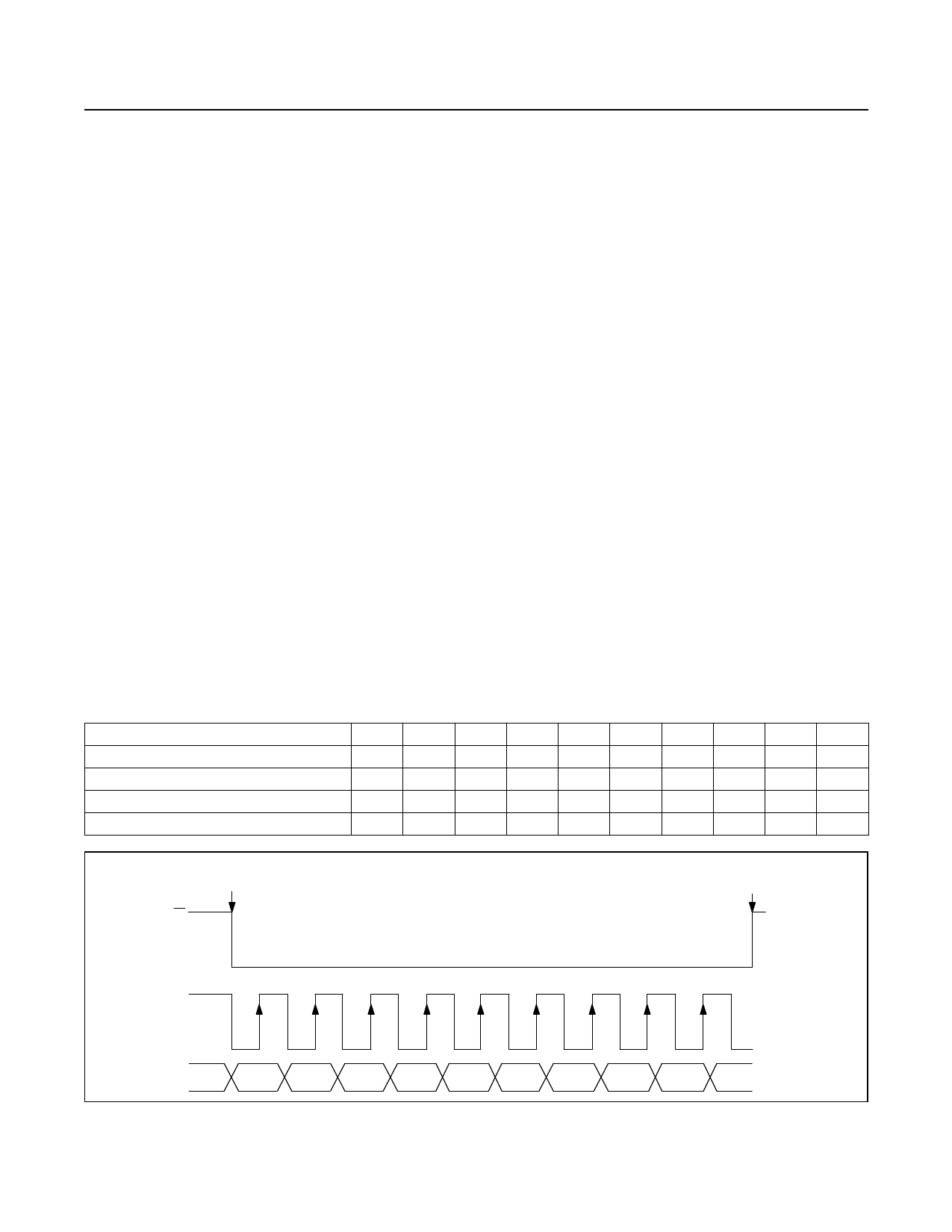

SPI Digital Interface

The MAX5391/MAX5393 include a SPI interface that pro-

vides a 3-wire write-only serial-data interface to control

the wiper tap position through inputs chip select (CS),

data in (DIN), and data clock (SCLK). Drive CS low to load

data from DIN synchronously into the serial shift register

on the rising edge of each SCLK pulse. The MAX5391/

MAX5393 load the last 10 bits of clocked data into the

appropriate potentiometer control register once CS transi-

tions high. See Figures 2 and 3. Data written to a memory

register immediately updates the wiper position. Keep CS

low during the entire data stream to prevent the data from

being terminated.

The first two bits A1:A0 (address bits) address one of

the two potentiometers. See Table 1. The power-on reset

(POR) circuitry sets the wiper to midscale.

Table 1. SPI Register Map

Bit Number

Bit Name

Write Wiper Register A

Write Wiper Register B

Write to Both A and B

1

2

3

4

5

6

7

8

9

10

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

0

0

D7

D6

D5

D4

D3

D2

D1

D0

0

1

D7

D6

D5

D4

D3

D2

D1

D0

1

1

D7

D6

D5

D4

D3

D2

D1

D0

COMMAND

STARTED 10-BIT

CS

WIPER REGISTER

LOADED

SCLK

DIN

A0

A1

D7

D6

D5

D4

D3

D2

D1

D0

Figure 2. SPI Digital Interface Format

www.maximintegrated.com

Maxim Integrated │ 9